The increasing demand for high-quality lubricants, steadily dwindling energy resources and changing market conditions are forcing lubricant manufacturers to look for new ways and processes to keep their products competitive or to produce new high-quality products.

EDL has been offering its customers in lubricant production a novel process for several years: LEPD technology (LEPD = Low Energy Polymer Dissolving). This is used for direct low energy melting of viscosity improvers (VI improvers) in the base oil. The advantages compared to the state of the art are impressive in terms of both plant operation and resulting product properties.

Background

Light and heavy lubricating oils have different viscosities depending on the temperature. To ensure optimum viscosity over a wide range of operating temperatures, so-called multigrade oils have been developed. These multigrade oils combine good cold start properties with good viscosity at higher temperatures. We achieve this by adding viscosity index improvers. VI improvers are additives that improve the viscosity-temperature behavior of oils.

Polymers are used as VI improvers, such as polymethacrylates, styrene-butadiene copolymers and others, which are usually provided as solid polymer bales. According to the state of the art, these solid polymers are mechanically comminuted in mixers and then dissolved in the lubricating oil. During the process, the polymers are exposed to very high shear forces and temperatures of 120 °C. Additionally, a long residence time of up to seven hours is required, which leads to aging and clouding of the lubricating oil and makes the use of antioxidants necessary.

Patented LEPD process

In the patented process, the polymer is melted with low energy in the base oil under pressure of up to 10 bar and temperatures below 100 °C in a liquefaction chamber under inert gas. Lubricating oil flows through the liquefaction chamber, which is enriched with polymer of more than 50 %. The enriched lubricating oil is mixed with other lubricating oil to achieve a polymer content of approx. 10 %.

Advantages and energy savings

The process saves about 30 % of time compared to the conventional production process. Due to the lower process temperature, the heat input is lower. Compared to conventional plants, it saves about 50 % of the required process energy. In addition, there is no risk of clouding or coking in the melting process, so that the final qualities of the finished oils are much higher and there is no need to use additional additives such as antioxidants. Since the polymer chain structure is not changed in the low energy dissolution process, better lubricating properties of the product can be achieved.

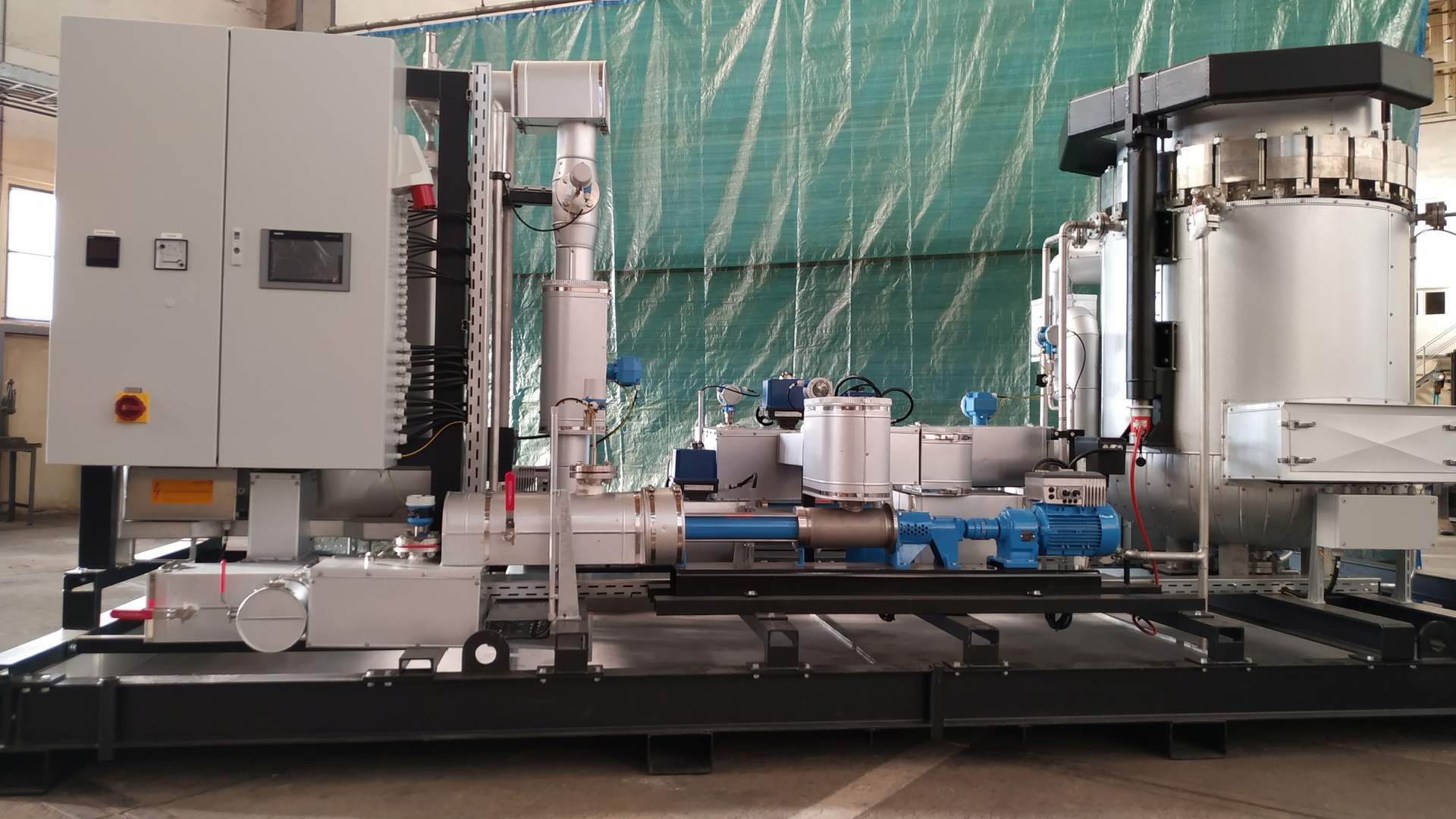

Pilot plant for on-site tests

EDL expanded its range of services for LEPD technology last year incorporating a pilot plant to provide customers with security for the design and planning of blending plants as well as for the desired product quality. Thermische Apparate Freiberg GmbH (TAF), a company of the Pöerner Group and specialist in the development of special solutions in plant engineering, has taken on this project. The planning, design, construction and manufacture of test and pilot plants is their domain. The technicians from Freiberg not only manufactured the pilot plant, but also mounted it on a skid, making it transportable and therefore directly useable at the customer’s site. With this plant, the customer can test his own lubricating oil formulations on site. The test results obtained can easily be transferred to an industrial plant scale.